With the amalgamation of Orient Refractories Ltd and Two Other Subsidiaries, RHI India and RHI Clasil in FY (21-22), the Merged Entity RHI Magnesita India Ltd has Emerged as an One-Stop Solution for All the Refractory Products, Systems and Service needs of its Global Customers.

Following which in January 2023, RHI Magnesita India Ltd has also Completed the Acquisitions of Dalmia OCL Limited and Hi-Tech Chemicals Limited’s Refractory Business. As a result company has now become the Refractory Market Leader in India, with a market share of 30% in the Indian Refractory Market.

The Integration has enabled the Merged Entity to Synergize, Simplify and Consolidate its Strength to Serve its Customers Better, by providing them a Single Refractory Solutions Platform offering the Industry’s Most Comprehensive Product and Solutions Portfolio, as an End-to-End Solution provider.

Besides, this Integration and Acquisitions-Led Inorganic Growth has also resulted in the Improved Allocation of Capital and Optimization of Cashflows contributing to the Overall growth prospects of the Newly Integrated Company, Creation of a Larger Asset Base and Facilitation of Access to Better Financial Resources, and Enhancement of the Shareholders Value pursuant to the ‘Economies of Scale’ and Improved Business Efficiencies.

RHI Magnesita India – The Perfect Proxy For India’s Infrastructure Growth

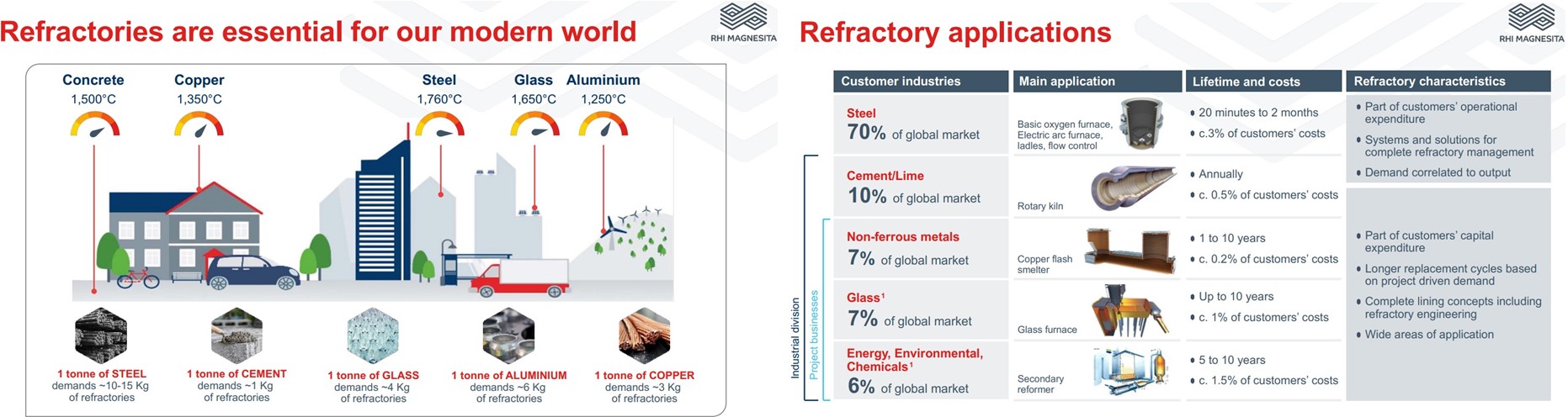

RHI Magnesita India is the Leading Supplier of High-Grade Refractory Products like Magnesia and Alumina based Bricks and Mixes, Isostatic Products and Specialized Flow Control Products like Slide Gates, Nozzles, etc. which are Indispensable for the Industrial High-Temperature Processes exceeding 1,200°C in a Wide Range of Industries including Steel, Cement, Non-Ferrous Metals, and Glass.

Given that the RHI Magnesita Group has 60% Ownership in the RHI Magnesita India Ltd, company has the Access to the Global R & D and Technical Expertise & Experience of the RHI’s Group, besides having the Ability to Offer the Heat Management Solutions Contracts with an Access to Global Product Range, Raw Material Security of Supply, and the Purchasing Power!

But, before moving ahead what are Refractory Products in the first place?

Without Refractories, Key industries such as Steel, Cement, Metals, Glass, Energy and Chemicals Could Not Function. Refractories Withstand Hostile conditions including Heat and Chemical Corrosion, Maintaining their Form and Functions at Temperatures over 1,200 °C. They Protect the Equipment’s such as Furnaces and Kilns against Thermal, Mechanical, and Chemical Stress.

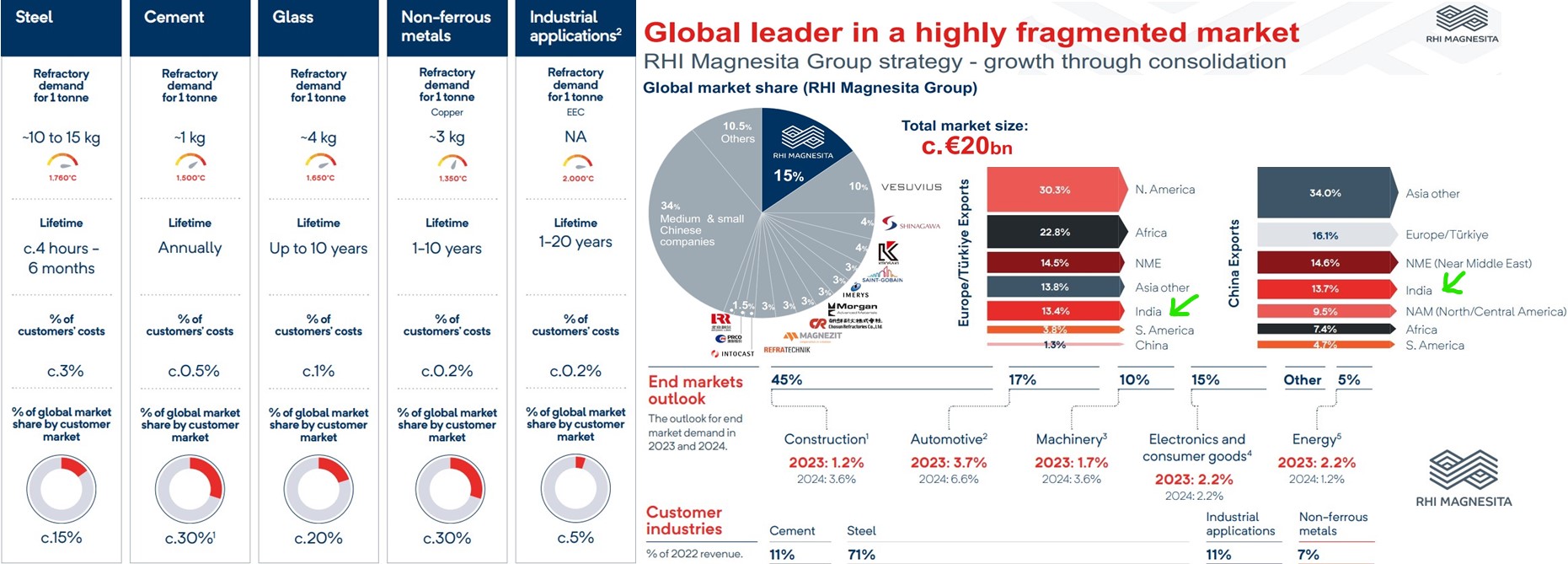

RHI Magnesita Group being the Leading Global Refractory Supplier, with ~ 15% Global Market Share and 30% ex-China, aims to Reduce movements of raw materials and finished goods and thereby to Lower the Costs and Improve Reliability and Security of the supply to its customers, has decided to Grow in Geographies and Product Segments (like Flow Control) in which it is Under-represented, in countries like India, Turkey, and China.

Hence given the Diverse Essential Applications of the Refractory Products and Services across the industries, this Global Leader in a Highly Fragmented Market is Expanding its Global Footprint with “Local For Local” Strategy in India and recent Acquisitions through Integrated Merged Entity – RHI Magnesita India Ltd, in January 2023 were part of these Strategic Investments to Support the Future Organic and In-Organic Growth, while building an Agile & Resilient Service Delivery System, with Strong Process Control.

Why & How Did RHI Magnesita Group Expanded Its Footprint In India?

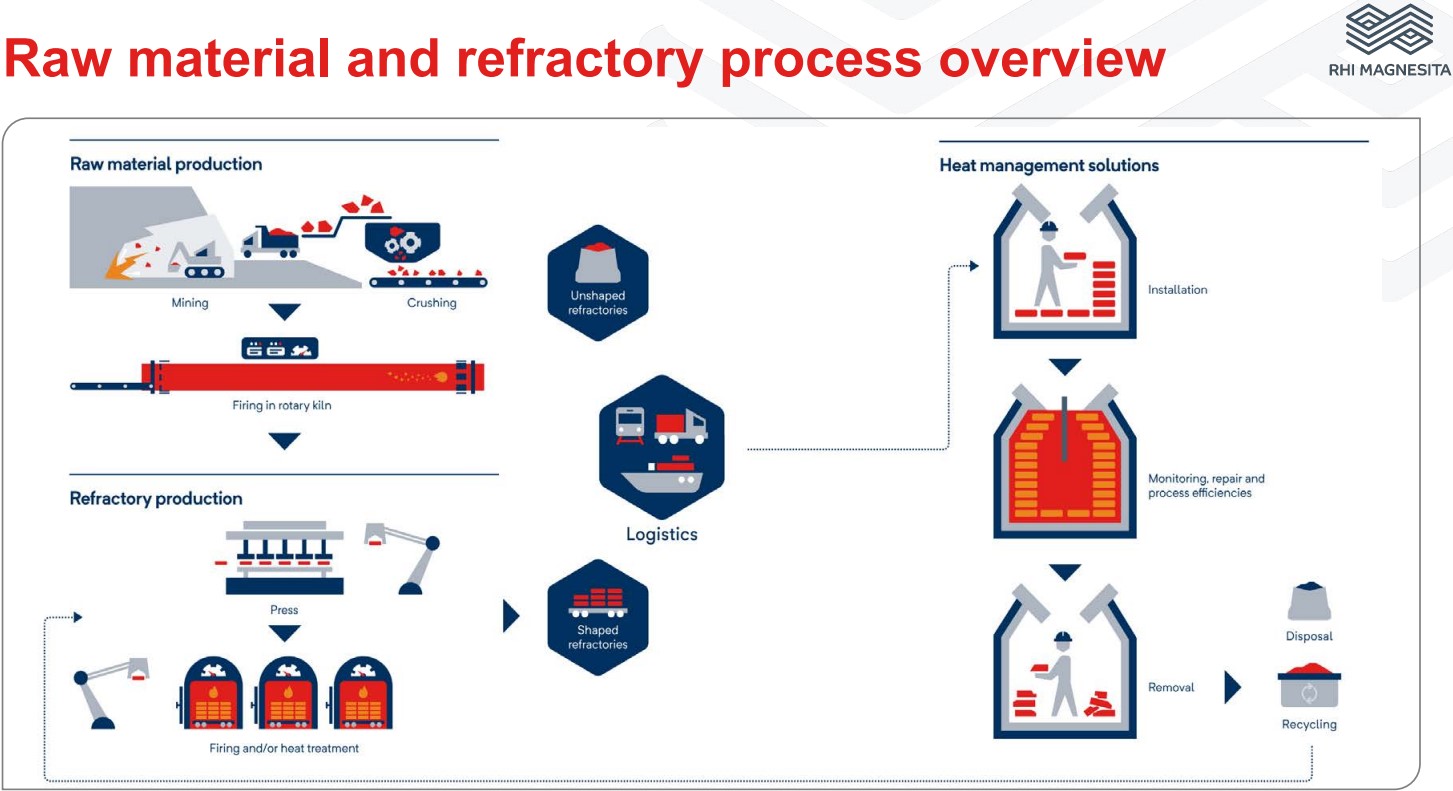

RHI Magnesita offers High-Quality Refractory Products, supported by its Industry-Leading R & D and Underpinned by their Vertically Integrated Structure which provides Security of Supply of Low Cost and High-Grade Magnesite Based raw material.

Company’s End-to-End Value Chain includes the Mining and Processing of raw materials, the Mixing, Pressing and Firing of Refractories, Logistics, Design, Installation, Monitoring, Recycling and Disposal.

Besides, RHI’s suite of digital products provides their customers with unrivaled Intelligence and Insights into the Refractory Lifecycle at their plants, Improving Productivity and Driving Efficiencies. Company’s Comprehensive Product Range and Expertise enables them to offer Full Heat Management Solutions to its customers, who are seeking to Improve Production Efficiency and Lower their Costs and Environmental Impacts.

Given Higher Refractory Products Consumption of ~ (10 to 15Kg) against per tonne of the Steel Produced along with Shorter Replacement Cycles of ~ (4 hours to 6 months) of Steel Refractories, Refractory Products and Solutions Sold to Steel Industries constitutes ~ 71% of the Total Revenue of the RHI Magnesita Group, followed by Cement, and the Industrial Applications at 11% each. Group has ~ 15% Global Market Share in the Steel Refractory Market.

Given 13.4% of the Exports from Europe and 13.7% of the Exports from China were being sent to India, as of FY22, so due to Ukraine – Russia War-led Supply Chain Disruption, Cost of Energy, Surcharges, and Freights has gone up very high. While the RHI’s Group was able to pass on the Increased Cost from European Raw Material Suppliers to its customers in North America and NME, However, it was more difficult to do the same with the customers in Asia.

In response to this Higher Energy Cost in Europe, Some of the production was Shifted to India eventually!

So, Why Did RHI Magnesita Expanded Its Footprint In India & Not Elsewhere In Asia?

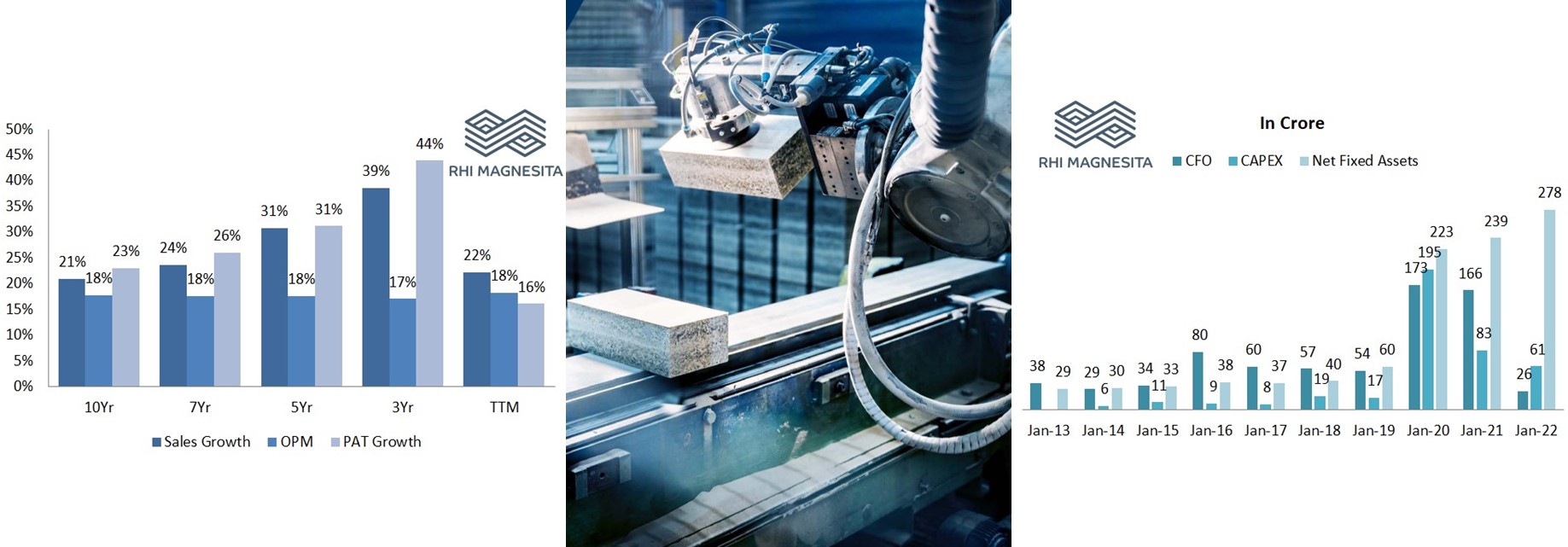

Even before the Merger of Orient Refractories Ltd with other Two Subsidiaries of RHI Magnesita Group namely, RHI India and RHI Clasil, company was growing really well at consistent OPM of ~ 18%. Amalgamation of these 3 companies in May 2021 has just taken the listed Merged Entity – RHI Magnesita India Ltd, to another level on the Growth Trajectory.

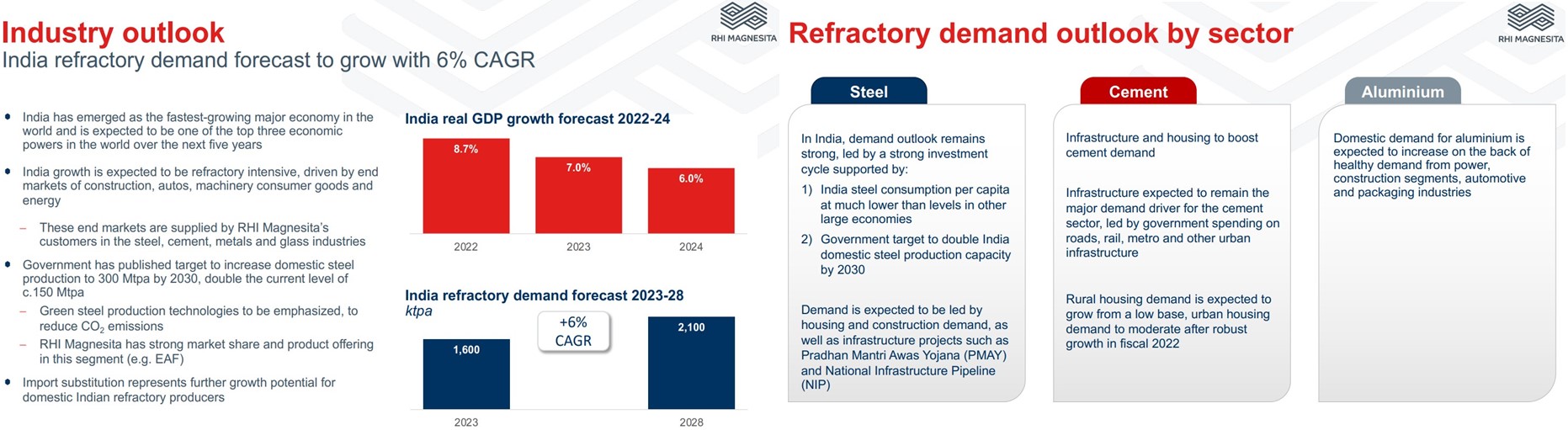

India has Emerged as the Fastest-Growing Major Economy in the World and is Expected to be one of the Top 3 Economic Powers in the World over the Next Five years. Since, this growth is expected to be Refractory Intensive, Driven by the End Markets of Construction, Autos, Machinery Consumer Goods and Energy – Therefore RHI Magnesita has a Long Runway of Growth & Opportunities here, as the company can easily Serve this Vast End Market across the Industries like Steel, Cement, Metals and Glass.

Further, Government has published its Target* to Double the Domestic Steel Production to 300 Mtpa by 2030, from the current level of 150 Mtpa, while emphasizing upon using the Green Steel Production Technologies to Reduce CO2 emissions – *- To know more about the Tailwinds in the Infrastructure Sector, read:

(https://jyadareturn.com/apl-apollo-tubes/ and https://jyadareturn.com/astral/)

Since, RHI Magnesita has a Strong Market Share and Product Offering in this Segment (e.g. EAF). So it becomes obvious choice for the Group to Expand here, as the CRISIL has Forecasted 6% CAGR Growth in India’s Refractory Demand between (2023-28). Besides, Import Substitution will only Augment the Further Growth Potential of the Domestic Indian Refractory Producers.

Therefore RHI Magnesita India Ltd is gearing up to fulfill the refractory demand that would be created going forward, by not only Expanding the Capacities of it’s Existing Plants but also through Acquisitions like Dalmia OCL Limited, and Hi-Tech Chemicals Ltd.

& How Did RHI Magnesita Planned This Expansion In India?

Recent acquisitions have created Balanced Portfolio of refractory products and a Strong Platform for Growth in India and the Wider region.

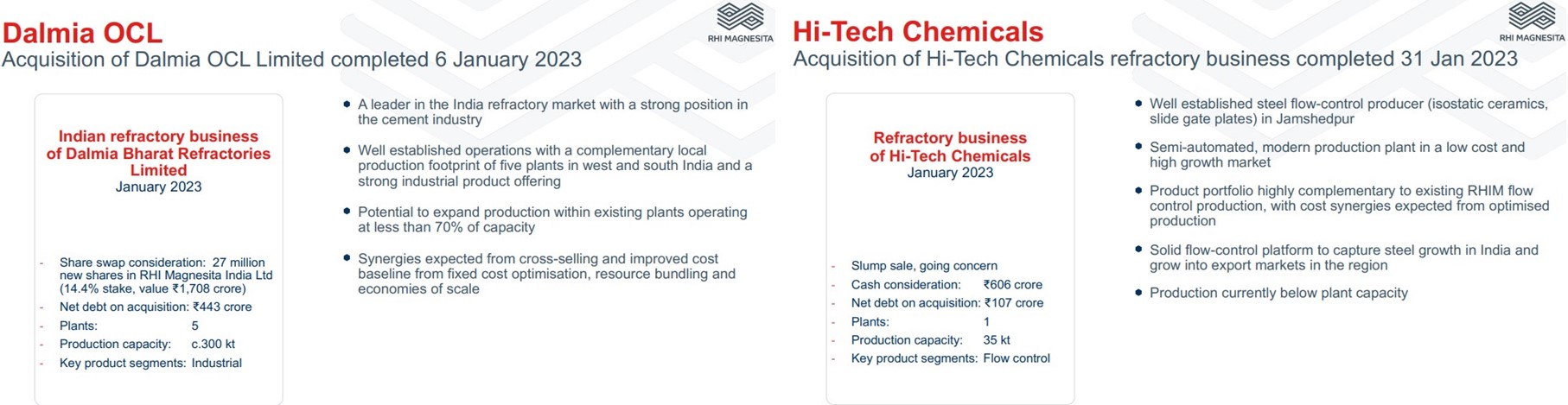

Dalmia OCL was having a Strong Position in the Cement Industry and well-established operations with a Complementary local production footprint of 5 Plants in the West and Southern India. Besides, it was having a Strong Industrial Product offering with a Potential to expand production within existing plants, which were Operating at Less than 70% of the Capacity, at the time of acquisition.

Hence Synergies are expected through this acquisition from, Cross-Selling and Improved Cost Baseline from the Fixed Cost Optimisation, Resource Bundling, and through Economies of Scale.

Similarly, Hi-Tech Chemicals was a well-established Steel Flow-Control Producer (Isostatic Ceramics, Slide Gate Plates) located in Jamshedpur and was having One Semi-Automated, Modern Production Plant in a Low Cost and High Growth Market.

It’s Product Portfolio was Highly Complementary to the existing RHI Magnesita’s Flow Control Production, with Cost Synergies expected from the Optimized Production through Solid Flow-Control Platform, to Capture Steel Growth in India along with Growth into the Export Markets in the region.

Here also Plant is Under-Utilised, as it was Running Below its Capacity at the time of acquisition.

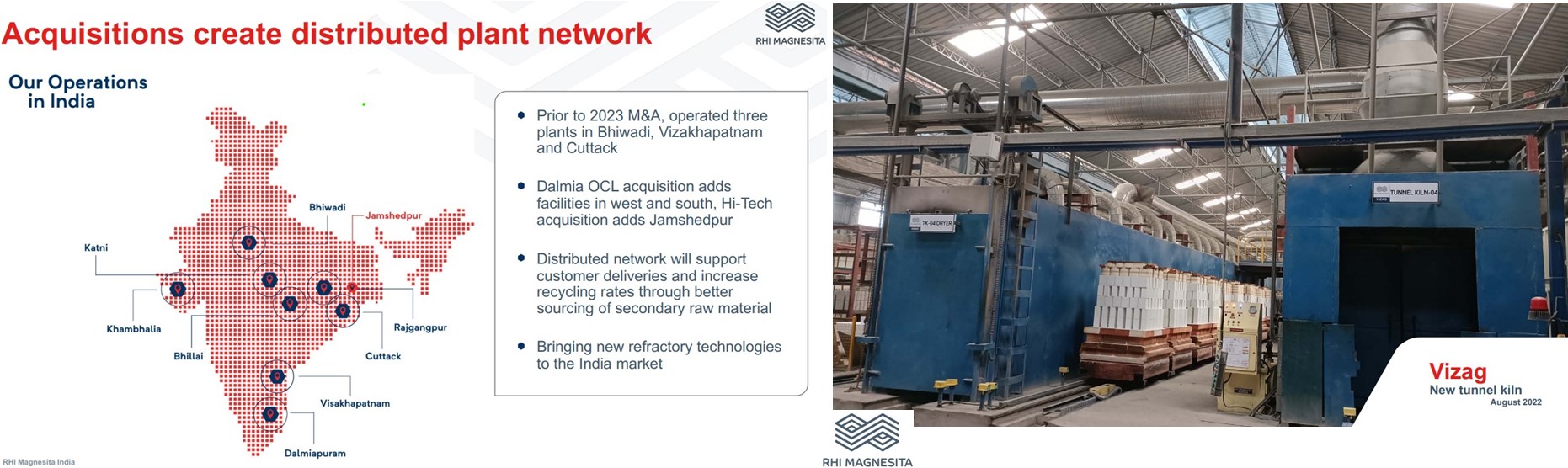

Prior to 2023 Merger & Acquisition, RHI Magnesita India was operating at 3 Plants in Bhiwadi, Vizakhapatnam and Cuttack. Dalmia OCL acquisition has added facilities in the West and South, whereas Hi-Tech acquisition has added the same in Jamshedpur.

This Well Distributed Network will Support the Customer Deliveries and Increase the Recycling Rates through Better Sourcing of the Secondary Raw Materials, while simultaneously Bringing the New Refractory Technologies to the Indian Refractory Market.

Backed By The RHI Magnesita Group, Listed Company In India Is Geared Up To Double Its Production & Revenue By FY26!

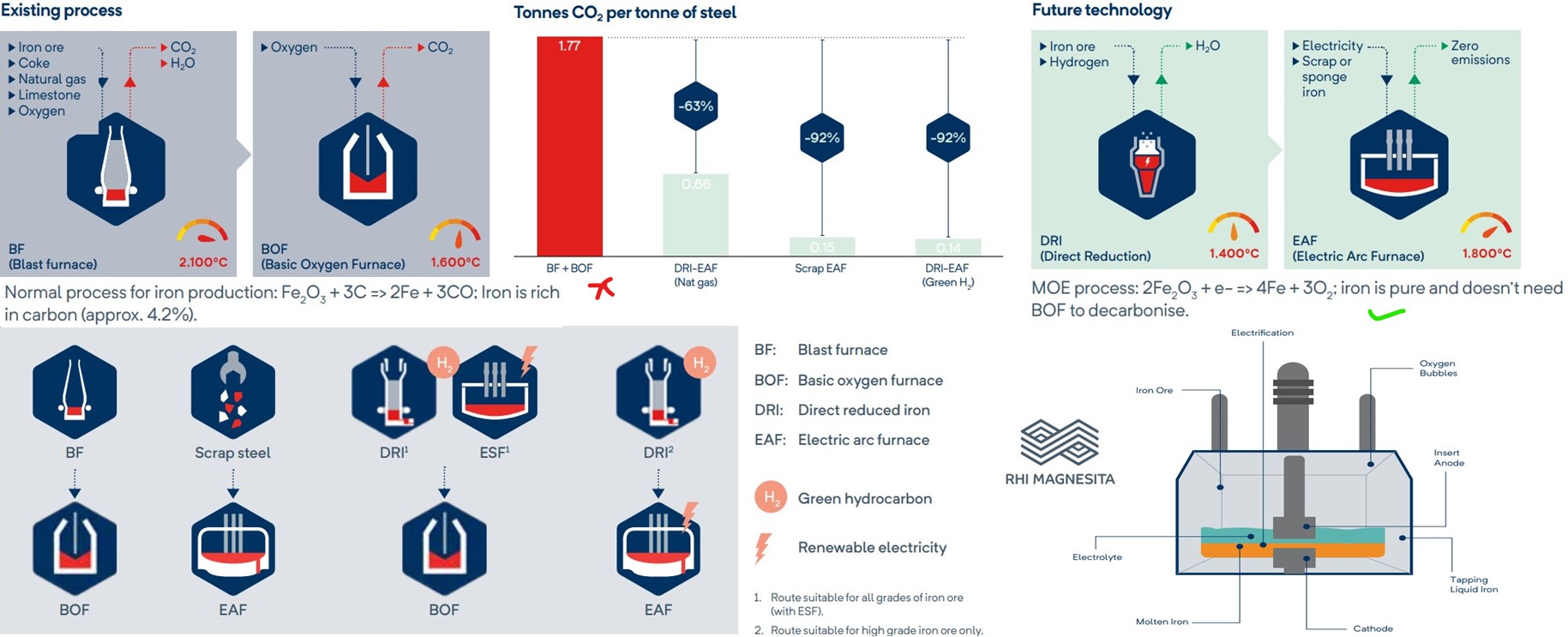

RHI Magnesita India’s Business is impacted by the dynamics of the steel industry in India and Worldwide. Besides, Refractories are a ‘Hard to Abate’ Industry with CO2 Emissions arising from the Fossil Fuel Use and Processing of Carbonate Raw Materials.

Therefore, High Capital Cost and Technological Challenges are involved in Operating this Business. Hence, RHI Magnesita Group is seeking to Transform Sustainable Business Practices in the Refractory Industry. As a result, Group has developed a Proprietary Novel DRI-Smelter Aggregate Technology to Utilize Recycled Refractory Material which Significantly Reduces Emissions – “Every tonne Recycled represents 2 tonnes of avoided CO2”.

This New Technology Lowers Ore-Grade requirements (therefore Lowering Barriers for Adoption and Upscaling) and produces liquid iron, Comparable to the hot metal of a blast furnace, at a Fraction of its CO2 emissions.

At the same time, this set-up Allows Steelmakers to Continue to Use Already Existing Equipment (e.g. Basic Oxygen Furnaces and Secondary Metallurgy), thereby Effectively Lowering the Capital Expenditure and Complexity required for the Implementation, while still making Significant Reductions in CO2 emissions to Comply with the Regulatory Authorities Directives.

While RHI Magnesita India Benefits from the Group’s R & D and Investments in Sustainable Technologies, their Clients get the Benefits of Reduced Downtime (due to Global Footprint), Lower Refractory Consumption, Lower Energy and other Raw Material Consumption, which leads to Cost Reductions and Higher Productivity!

Company has earlier aimed to Double its Production from 1.5 Lakh tons per annum in FY21 to 3 Lakh tons per annum by FY26, which it was going to achieve through organic and inorganic means, by Phased CapEx of 400 million Euro between 2021-26 for Expanding capacities and Automation of company’s Three Plants at Bhiwadi, Vizag, and Cuttack, But with Acquisitions of Dalmia OCL Limited and Hi-Tech Chemicals Limited it’s Production Capacity has already gone beyond 5 Lakh tons per annum and company at present is having ~ 1.5 Lakh tons per annum of Capacity Un-utilised i.e. Company has already exceeded the Target Production of 3 Lakh tons per annum!

Therefore out of Total CapEx of 400 million Euro, almost 370 million Euro has already been spent on above acquisitions and remaining ~ 30 million is the Only CapEx left to be spend in next 3 to 5 years time.

In FY21, company has already increased the Non-basic Brick making capacity of the Vizag Plant by ~ 30%, as it Operationalized a New Tunnel Kiln there. Further, the Capacity Expansion of the basic Bricks making facility at the Cuttack Plant is under progress and is expected to take Pace by FY24. Once completed, it will help the company in Chinese Import Substitution.

RHI Magnesita India – Outlook For Q4FY23 and Beyond

Since ~ 90% of the Planned CapEx has already been done through Acquisitions Completed in January 2023, so going forward company doesn’t have any major CapEx Left to deal with, other than to Automate or Upgrade its existing Plants.

Further as the company has taken Debt of ~ Rs. 1070 Crore to fund these acquisition, so now in February 2023 company’s board has approved raising the further capital, via issue and allotment of additional equity shares of Rs. 1,500 Crore, to First Repay this Debt of Rs. 1,070 Crore and then to utilize remaining capital of ~ Rs. 400 Crore for general corporate purpose, to ensure fund availability to grab if any Potential acquisition opportunity emerges in the near future!

EBITDA in Q3FY23 was declined by 11% due to Higher Cost of Trading Goods, arising out of the Energy Cost Hikes in Europe, and the Foreign Exchange Fluctuations. Since it may take few more months for the High Cost Inventory to get Exhausted, hence even Q4FY23 may see more or less similar impact of Higher Cost of Trading Goods on the EBITDA Margins, but from Q1FY24 things are likely to get better.

Besides, as the Steel Production is expected to be growing at ~ 10% to 12% in the coming years, hence the Demand from this Industry will keep on Driving the Demand of Refractory Products & Solutions from the RHI Magnesita India Ltd.